As the core functional unit of a hospital, the operating room's operational efficiency directly affects medical safety and resource utilization. According to the "Guidelines for Operating Room Nursing Practice" and JCI (Joint Commission International) standards, the surgical process needs to achieve closed-loop management throughout the entire process, requiring standardized operations, real-time monitoring, and traceability for patient transportation, specimen delivery, and other links.

The traditional "manual calling and paper recording" mode not only leads to medical staff wasting energy in complex coordination work, but also may cause serious medical safety hazards due to delayed pick-up and drop off and opaque specimen circulation. Therefore, the use of IoT technology to break the "blind" state of the operating room and achieve full chain visual management from patient access to specimen submission has become a key breakthrough point in improving quality control and operational efficiency in the construction of modern smart hospitals.

Why is the operating room efficient

Always unable to bring it up?

hit the pain point

Lack of process control

When will the patient leave the ward? When will we arrive at the operating room? Is the specimen delivered to the pathology department on time? The lack of real-time node records throughout the process is like opening a blind box.

Scheduling without basis

The scheduling of nursing staff relies on experience and paper records, resulting in a shortage of manpower during peak periods and idle waiting between surgeries. During low peak periods, manpower is wasted and cannot dynamically match nursing staff resources with fluctuations in surgical volume, which contradicts the principle of "dynamic resource allocation" in the "Guidelines for the Construction of Hospital Operating Departments".

Difficult to meet quality control standards

Lack of objective data support makes it difficult to meet the strict requirements of JCI standards for "full process traceability" and WHO's recommended "30 minute golden transfer window".

Chaotic asset management

The storage, retrieval, and disinfection of surgical kits, instruments, and consumables rely on manual registration, which is prone to errors and difficult to achieve closed-loop management throughout the entire lifecycle.

Smart surgical transportation management system

Three core advantages

Solution

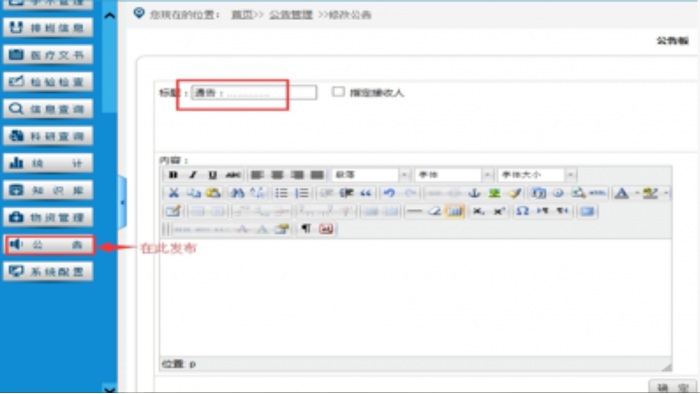

In response to the pain points in the above-mentioned industries, Likang has launched the "Smart Surgical Transport Management System", which deeply integrates RFID IoT technology and intelligent scheduling algorithms to build a closed-loop ecological management system for medical staff that manages people, objects, and processes.

Smart surgical transportation management system

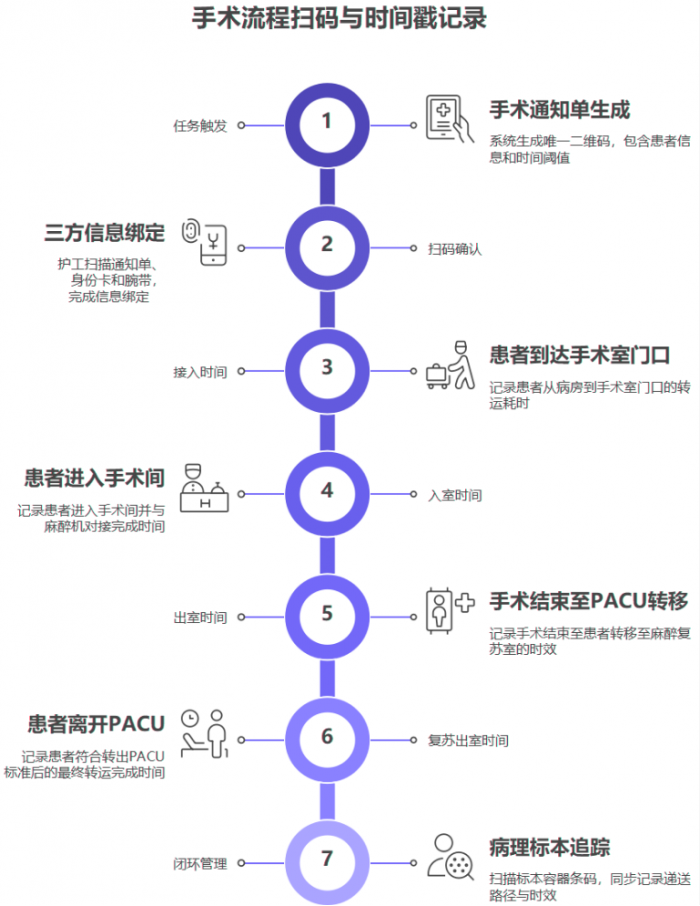

Task trigger ->Scan code binding ->

Key Node Check in (Access/Entry/Exit/PACU) ->Closed loop End

Full process node tracking, completely bid farewell to "blind box" transportation

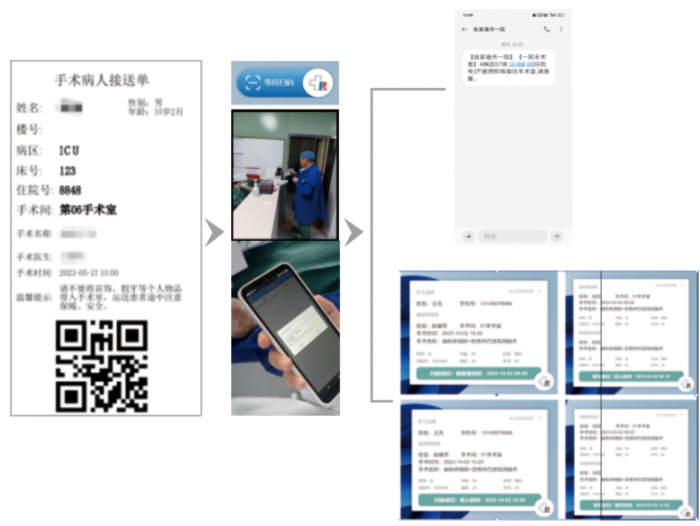

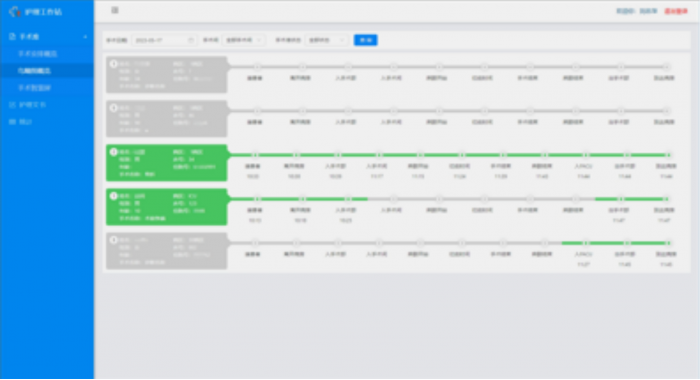

The system introduces the concept of "surgical flight accuracy" and uses a PDA barcode gun to achieve tripartite scanning and binding of "patient+caregiver+task list". From ward access and room entry docking, to postoperative resuscitation and return to the ward, timestamps are automatically generated for each critical node. The dispatch center monitors the status of all tasks in real-time through Gantt charts. Once a timeout occurs (such as a delay of more than 15 minutes), a yellow warning is triggered, changing the management from "post event intervention" to "pre event intervention".

Surgical QR code scanning

Surgical room transportation of patients and specimen management

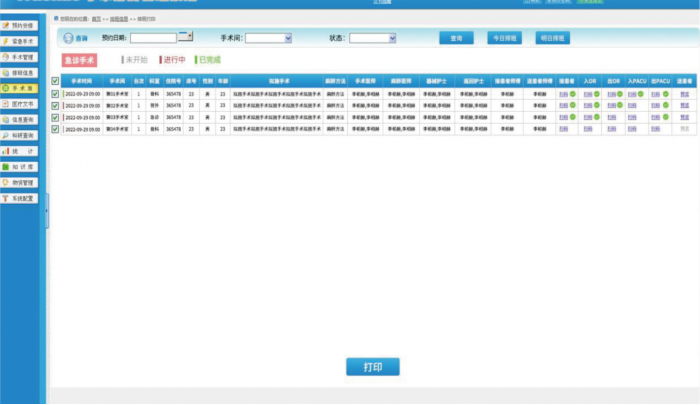

Real time surgical status

Intraoperative panoramic visualization recording system

Surgical dynamic management

Effective communication and management among family members in the operating room

Both computer and mobile devices can be operated

RFID intelligent IoT, building a 'secure lock' for assets and specimens

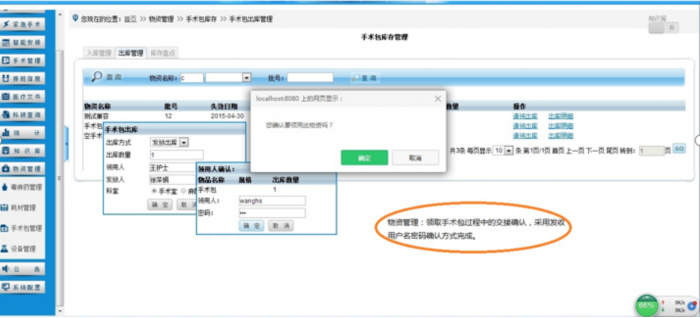

The system utilizes RFID chip technology with high temperature resistance and high reuse rate to solve the problem of material management.

Specimen safety

Strictly lock the time from the departure of the specimen to the signing of the pathology department to ensure compliance with medical quality control standards and avoid the risk of sample degeneration.

Dynamic operation management of surgical kits and consumables

Efficient inventory

Support batch group scanning of equipment packages, which can accurately identify even if labels are stained or items are stacked. It not only prevents leakage scanning, but also improves inventory efficiency to seconds, achieving full lifecycle traceability from storage, use to recycling and disinfection.

Data driven decision-making provides evidence-based management

Data driven decision-making provides evidence-based management

The system no longer lets data sleep, but automatically generates multidimensional reports. Accurately analyze the efficiency and workload of caregivers through KPI heat maps, and assist in scheduling optimization; By calculating the on-time delivery rate of surgeries and the efficiency of specimen circulation, we provide solid data support for hospitals to pass Level III Grade A re examination and JCI certification, truly achieving lean operational management.

Analysis of Operating Room Transport Nursing Operation

Visible efficiency leap

Value implementation

The digital transformation brings not only standardized processes, but also tangible benefits. According to practical application calculations, the system can help increase the utilization rate of operating room resources by more than 15%, significantly reduce the error rate of nursing workload statistics by 90%, and stabilize the on-time delivery rate of specimens at over 98%.

At the same time, this intelligent surgical transport management solution, which integrates full process visualization monitoring, intelligent scheduling, and multidimensional data analysis, has reshaped the "central nervous system" of the operating room through technological means. It not only solves the current pain points in manpower and processes, but also supports hospitals to easily cope with various high standard quality control assessments with precise quantitative data, allowing operating room management to truly enter a new era of efficient, safe, and compliant intelligence.

Say goodbye to extensive experience management and embrace precise data decision-making. This is not only an iteration of technology, but also a profound change in the operating room operation mode. Let's use full process visualization as a starting point to thoroughly clear the "hidden bottlenecks" in the life channel, while ensuring the bottom line of medical safety, injecting strong intelligent momentum into the high-quality development and international certification of hospitals.

Heal Force Intelligent Manufacturing brings warmth to technology, strengthens protection, and makes life healthier.

Welcome to inquire by phone

400-820-6276

[Disclaimer] Some of the information in this article is sourced from the internet. If there is any infringement, please contact us for deletion

沪公网安备31011802003750号

沪公网安备31011802003750号