As the first line of defense for protecting personnel, environment, and samples in the laboratory, the importance of biosafety cabinets is self-evident. However, in the busy daily experimental work, we often overlook the key details and maintenance related to safety, which may not only lead to precious sample contamination, but also expose experimental personnel to potential biological hazards. Therefore, mastering the correct SOP and selecting high-performance equipment are compulsory courses for every researcher.

highlight the key points

Textbook level operational SOP

In order to ensure experimental safety and operational standards, it is recommended to strictly follow the following core steps:

The 'sense of ceremony' before the launch

》Fully armed: wear protective clothing, gloves, and masks.

》Preparation disinfection: Use 75% alcohol to thoroughly wipe the workbench and inner walls.

》Airflow preheating: Turn on the fan, open the glass window to the safety mark, and wait for the equipment to run stably before starting to work.

The 'Golden Rule' in Operations

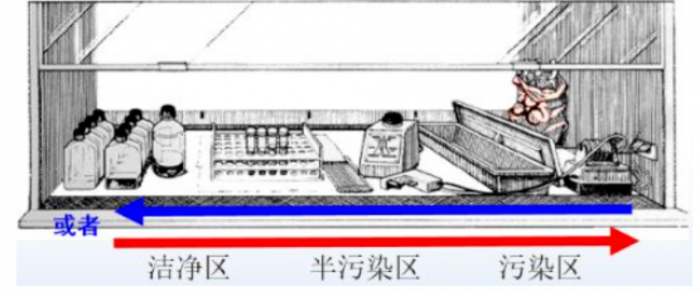

》Partition operation: Strictly implement the "clean area" policy ➡ semi-contaminated area ➡ The principle of placing items in polluted areas is to avoid cross contamination.

》Airflow protection: Do not place objects at the intake grille, strictly prohibit blocking the return air outlet, and ensure that the airflow barrier is intact.

》Gentle movements: Avoid rapid arm movements that interfere with airflow, and all operations should be performed in the non porous area of the workbench.

The 'art of clearing the scene' after the end

》Return to original location: Remove all items and disinfect the surface with 75% alcohol again.

》Circulating purification: Maintain the operation of the fan for a period of time to discharge residual pollutants.

》Sterilization record: Turn off the fan and glass window, turn on the ultraviolet lamp for sterilization, and carefully fill in the "Operation Record".

knock on the blackboard

Graded maintenance and upkeep

Equipment is like comrades in arms, careful care is necessary for long-term companionship:

Daily/Weekly Maintenance

Suggest using a flexible cleaning agent to wipe the exterior and glass, and check if all functions are sensitive.

Monthly maintenance

Remove the external dust, conduct deep disinfection and sterilization for the interior, and check the safety facilities.

Annual maintenance

Key link!

Professional personnel are required to conduct pressure attenuation testing and replace UV lamps (recommended annually) and fluorescent lamps (recommended every two years).

ABOUT Regarding Experimental Safety

Operation and maintenance of biosafety cabinets

SOP, Have you learned?

Advanced Choice

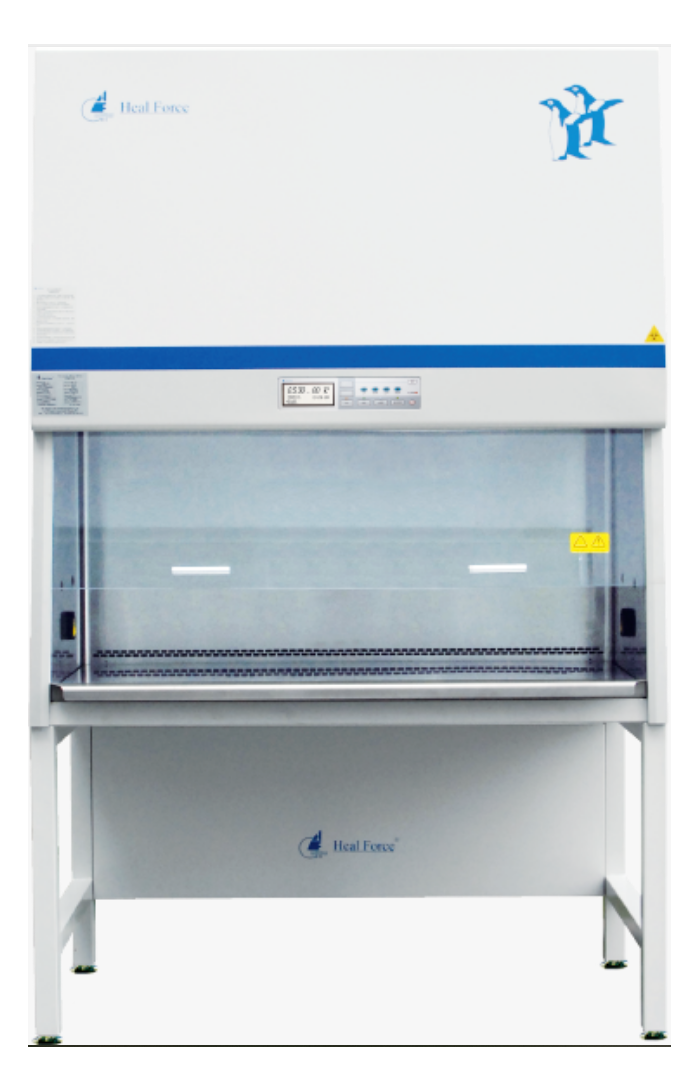

HFsafe LC series biosafety cabinet

As one of the drafting units of China's biosafety cabinet industry standards, Heal Force brings you the HFsafe LC series biosafety cabinets to safeguard your scientific research experiments.

Why choose HFsafe LC series?

■ Authoritative endorsement: Through multiple certifications such as ISO, CFDA, CE, and EN12469, our quality is benchmarked against international standards.

■ Ultra clean filtration: using imported ULPA filters, the filtration efficiency is as high as 99.9995%, far exceeding ordinary standards.

■ Intelligent perception: equipped with a light wind speed sensor and automatic wind speed compensation function, real-time dynamic display of wind speed, and filter life display and failure alarm, making safety visible.

■ Humanized design: unique control panel bar code display, intuitive and convenient operation.

Overview of Application Scenarios

Choose the Heal Force HFsafe LC series biosafety cabinet

Choose international level security protection

Build a copper and iron wall with intelligent technology

Make the path of scientific research worry free

Professional equipment with standardized operation

Guarding every peaceful experiment for you

For more details, please feel free to call us for consultation

400 820 6276

【声明】本文部分资料来源于网络,如有侵权,请联系删除

沪公网安备31011802003750号

沪公网安备31011802003750号