With the rapid development of modern medicine, various advanced surgical instruments continue to emerge. Endoscopic, microscopic, and robotic surgical instruments have made the structure of the instruments more complicated. In order to better assist the cleaning, disinfection and sterilization of medical equipment, prevent and control hospital infections, and ensure the safe implementation of various diagnosis and treatment technologies, Heal Force launches Hydrogen Peroxide Plasma Sterilizer, which is one of the star products of Heal Force operating room series.Heal Force Hydrogen Peroxide Plasma Sterilizer has the advantages of short sterilization cycle time, convenient operation, environmental protection and safety.

Heal Force Hydrogen Peroxide Low Temperature Plasma Sterilizer kills germs through the following functions during the sterilization process.

①Environmental protection and safety

Hydrogen peroxide solution is the medium, which is excited by a specific electromagnetic field to form plasma and complete the sterilization. The final product is a small amount of water vapor and oxygen, with no toxic residues and discharge, no harm to medical staff and no pollution to the environment.

②Quickness and efficiency

The sterilization cycle is short, the standard mode and the fast mode are free to choose. There is no need to use other enhancement methods for complex luminal equipment. The equipment can be used directly after the sterilization is completed, reducing the loss of valuable equipment and the amount of spares.

③Simple installation

The standard door can be passed through, and the four-wheel movement is light, which saves the hospital's related configuration equipment and site resources.

④Convenient operation and monitoring

The touch screen design is clear and intuitive and easy to operate. The automatic monitoring system will automatically monitor the operating parameters of the system. If an abnormality occurs, it will automatically terminate the sterilization process, report and indicate the point of failure to ensure the healthy operation of the equipment.

⑤ Low temperature sterilization

The temperature in the sterilization chamber is about 55°C, which will not damage the equipment and items, can prolong the service life of valuable medical equipment, and have a good sterilization effect.

⑥Safety and stability

The system has a strict automatic detection function, real-time monitoring of the sterilization process, if there is an abnormality, the system will automatically alarm.

Preparation period: Make the vacuum in the sterilization chamber reach the vacuum condition of plasma discharge, and simultaneously help to drive away the residual moisture on the surface or inside of the sterilized items.

Injection period: The system automatically injects a hydrogen peroxide solution with a concentration of 58%-60%.

Diffusion period: The hydrogen peroxide solution enters the sterilization chamber, vaporizes and diffuses instantaneously, and is evenly distributed in the entire sterilization chamber.

Plasma period: The hydrogen peroxide molecules generate plasma under the action of radio frequency, which can intervene and destroy the generation of microorganisms, and play a role in killing microorganisms. When the radio frequency stops, the plasma is converted into stable oxygen molecules and water Molecule, non-toxic and hazardous substance residues.

Ventilation period: The ventilation valve is opened to allow the filtered clean air to enter the sterilization chamber. When the negative pressure in the chamber returns to normal pressure, the sterilization ends.

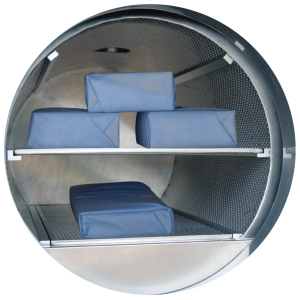

The effective sterilization volume is 100L, and the cylinder depth is 810mm.

It can reduce the overall cost of sterilization and improve efficiency.

Plasma Sterilizers have a wide range of objects and can be used for metal and non-metal products, especially for non-high heat-resistant items and non-humidity-resistant items, mainly including sports medicine, gynecology, surgery, ENT, ophthalmology, urology and other laparoscopic instruments. Such as arthroscopy, laparoscopy, sinus endoscopy, electric resection scope, ureteroscope, coagulation line, electric drill, electric saw and other items sterilization.

Heal Force has been deeply engaged in the field of medical devices for more than 30 years, and Heal Force products are distributed in more than 100 countries and regions around the world. Since Heal Force Hydrogen Peroxide Low Temperature Plasma Sterilizer's launch, it has been highly recognized by a large number of customers. In 2020, it was selected into the catalog of excellent domestic medical equipment products.

沪公网安备31011802003750号

沪公网安备31011802003750号